- info@slssupply.co.uk

- +44 (0) 1277 849272

Padlocks

■

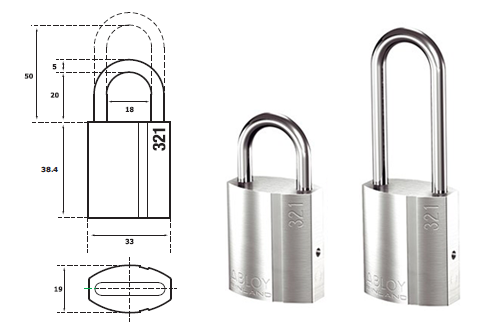

PL321/20

PL321/50

Mechanisms:

Sentry, Protec

■

Safety and security

Brass bodied padlocks

Stainless steel open shackle

■

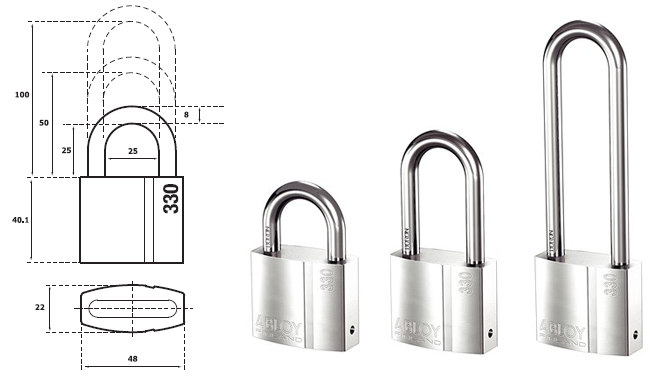

PL330B/25

PL330B/50

Mechanisms:

Sentry, Protec

■

PL330/25

PL330/50

PL330/100

Mechanisms:

Sentry, Protec, Novel

■

Safety and security

Brass bodied padlocks

Brass open shackle

■

Security

Brass bodied padlocks

Boron steel open shackle

BS EN 12320 approved (excluding PL330/100)

Grade 3

■

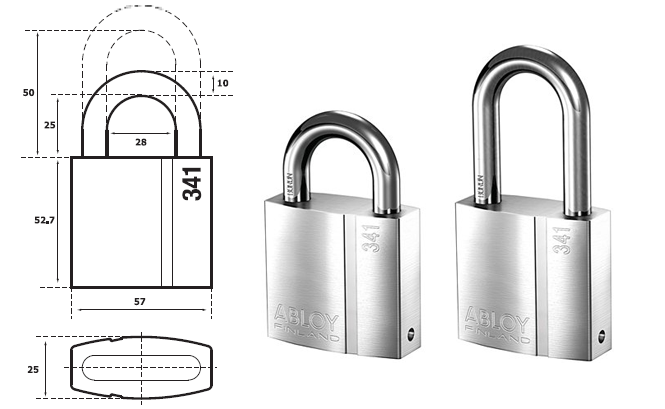

PL341/25

PL341/50

Mechanisms:

Sentry, Protec

■

Security

Brass bodied padlocks

Boron bodied padlocks

Boron case hardened

Steel open shackle

BS EN 12320 approved

Grade 3

■

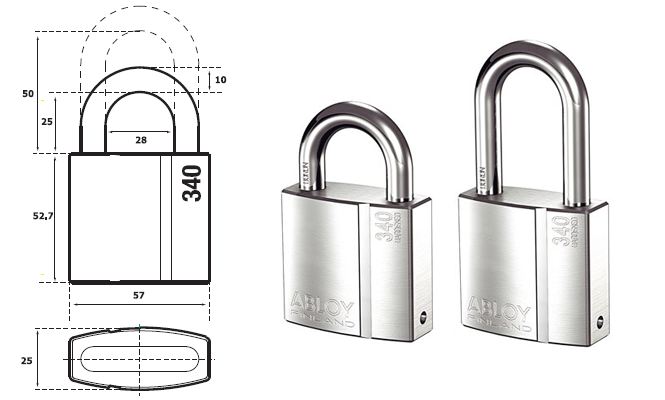

PL340/25

PL340/50

Mechanisms:

Sentry, Protec, Novel

■

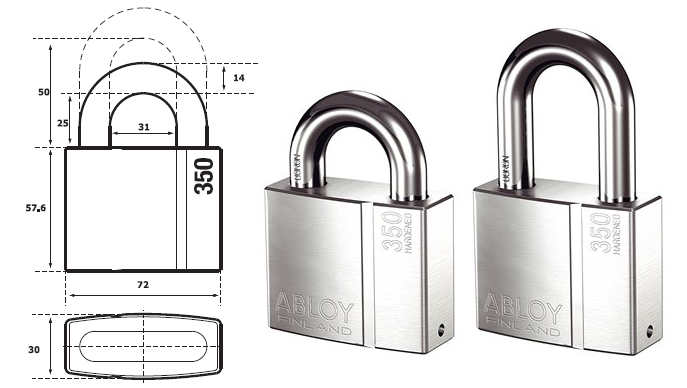

High Security

Case hardened steel bodied padlocks

Boron case hardened steel open shackle

BS EN 12320 approved

Grade 4

■

PL350/25

PL350/50

Mechanisms:

Sentry, Protec

■

Maximum Security

Case hardened steel bodied padlocks

Boron case hardened steel open shackle

BS EN 12320 approved

Grade 5

■

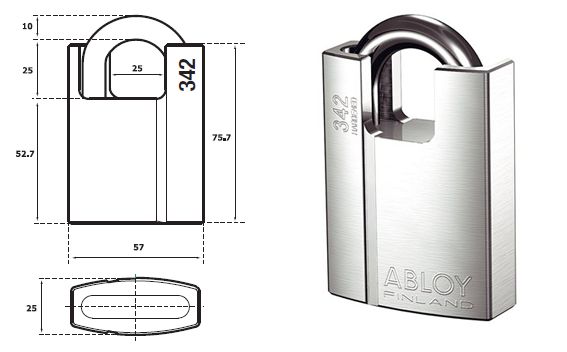

PL342

Mechanisms:

Sentry, Protec

■

High Security

Case hardened steel bodied padlocks

Boron case hardened steel open shackle

BS EN 12320 approved

Grade 4

■

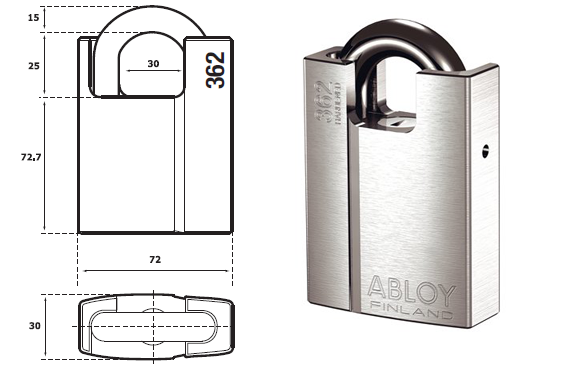

PL362

Mechanisms:

Sentry, Protec

■

Maximum Security

Case hardened steel bodied padlocks

Boron case hardened steel open shackle

BS EN 12320 approved

Grade 6

Standards

ABLOY padlocks have been designed not only to meet the European Standard BS EN12320, but to exceed them. We rigorously assess the durability of our padlocks with tests such as the acetic acid salt-spray test, which ensures that our padlocks can withstand the elements when used in exposed locations.

The quality system used in the ABLOY factory meets the requirements of the international Quality System Standard ISO 9001 (corresponds to the USA Standard ANSI/ASQC Q91) plus ISO 14001.

BS EN12320 Requirements BS EN Grade

| Requirement | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Minimum no. of differs | 300 | 1000 | 2500 | 5000 | 10000 | 20000 |

| Pulling of shackle/staple (kN) | 3 | 5 | 15 | 30 | 70 | 100 |

| Twisting of shackle/staple (Nm) | 40 | 100 | 200 | 450 | 1200 | 2500 |

| Cutting of shackle/staple (kN) | 6 | 15 | 25 | 35 | 70 | 100 |

| Blow on shackle/staple (x 5 times) (weight/g x height/mm) |

1250×800 | 3050×1000 | 6550×1400 | 7150×1500 | ||

| Test temperature | -20 C | -20 C | -40 C | -40 C | ||

| Blow on lock body (x 5 times) (weight/g x height/mm) |

1250×800 | 3050×1000 | 6550×1400 | 7150×1500 | ||

| Load on cylinder plug or locking mechanism (kN) |

4 | 5 | 10 | 15 | ||

| Drilling (minutes) | 4 | 5 | 10 | 15 | ||

| Sawing (minutes) | 2 | 4 | 8 | |||

| Torque resistance of cylinder plug (Nm) |

5 | 15 | 20 | 30 |